Challenges

Together with the customer we defined what would be the main goals during the product development:

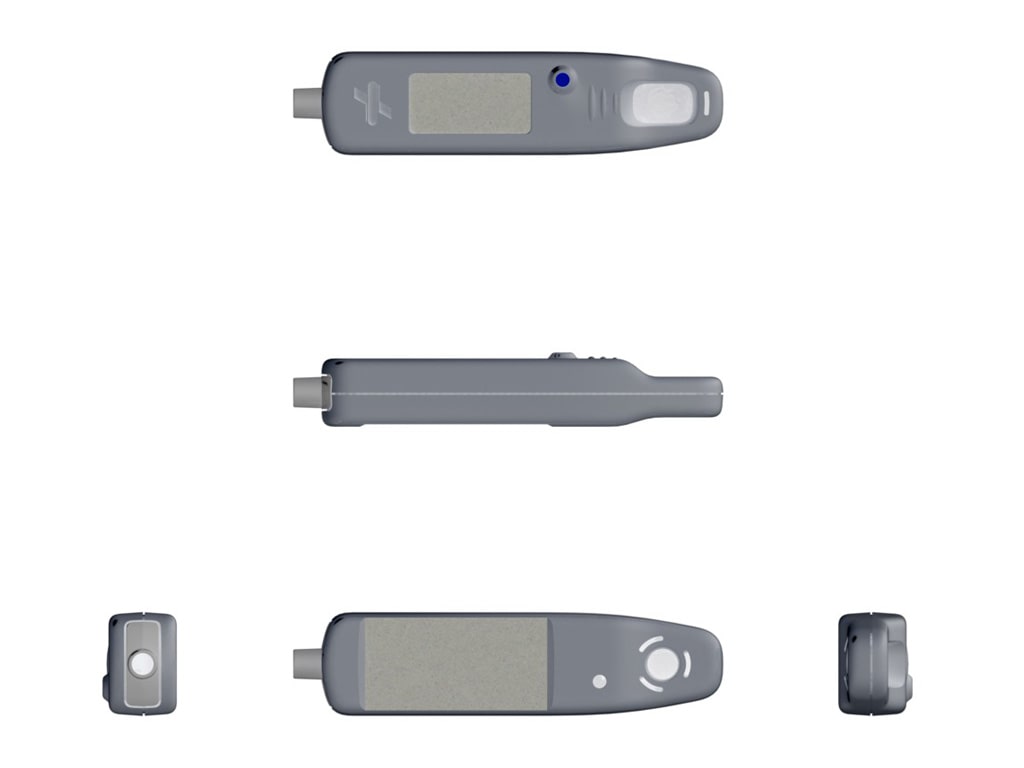

- no physical seals to facilitate installation and/or maintenance,

- applicable not only to vehicles but also to cold-store rooms,

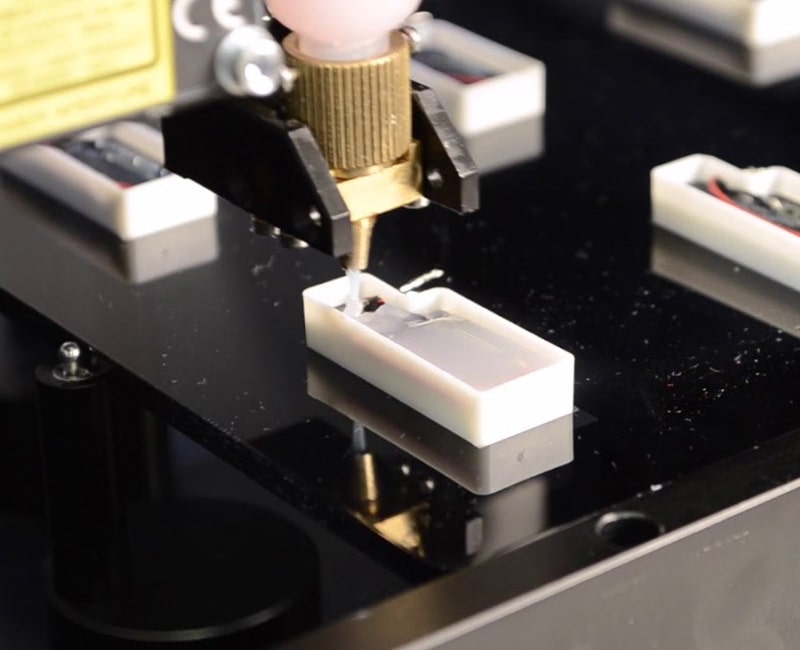

- the case will have a double function to work as a ergonomic and robust enclosure and as a mold for the potting process.

Solutions

As opposed to the low-pressure molding process, the potting process involves many steps and requires a long curing period that increases the cycle time and can be conducive to shrinking, putting the electronic components at risk.