Challenges

The main inputs from customer:

- an extremely robust product construction,

- distinctive aesthetics to make it easy to differentiate from competitors and

- LED to be visible independently of the connection orientation to the tachograph.

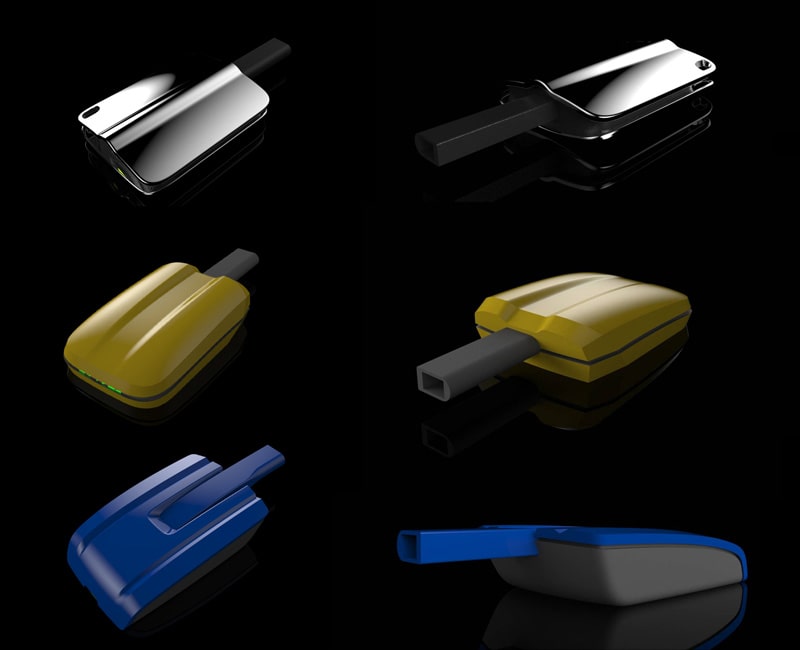

Conceptual Design

The creative team explored different shapes and geometries. One of the main goals was the visual integration of the connector arm with the body.