Challenges

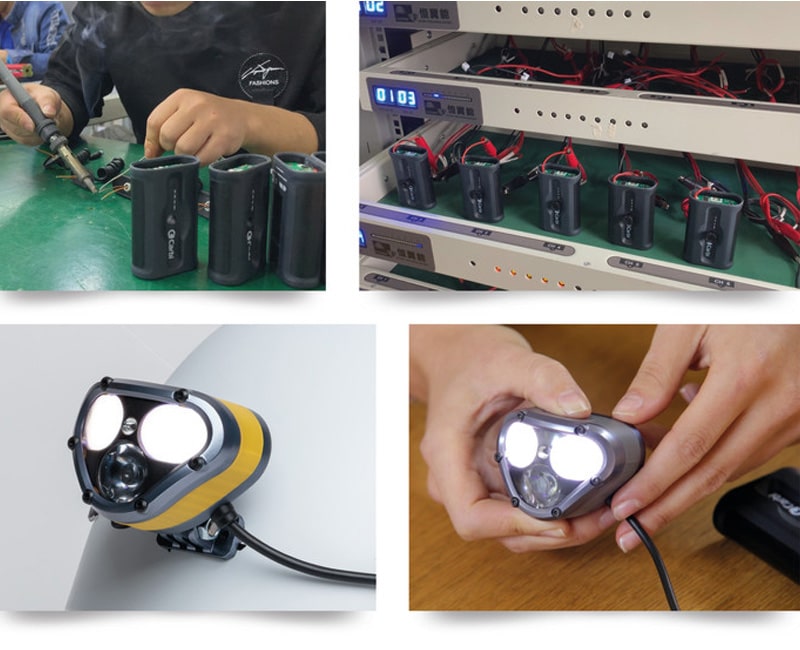

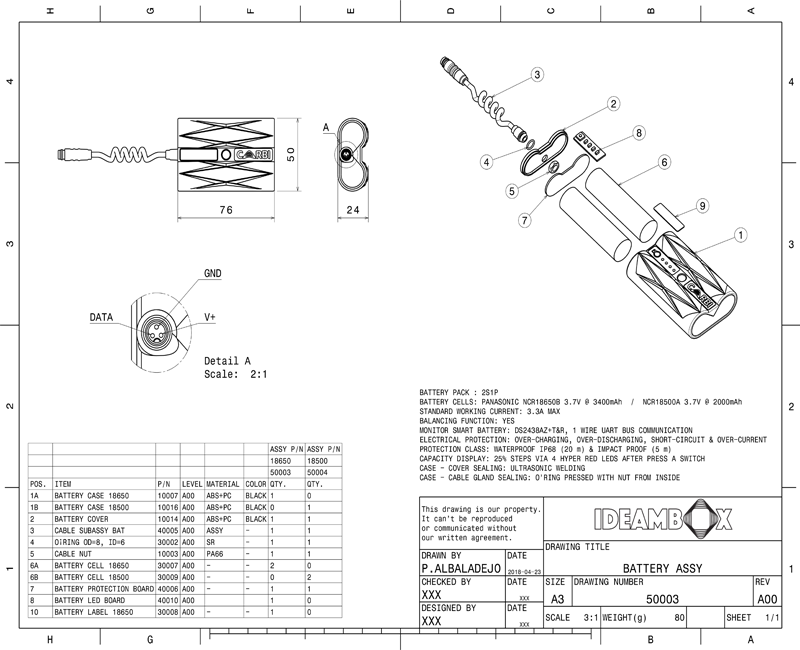

We designed Carbi with two main goals, an extremely robust and reliable product construction for working in extreme conditions including water submersion and an innovative design and lighting technology able to cover the user peripheral view.

Solutions

Initially we experimented with remote phosphors that allowed to transfer and deliver light through the entire surface of a customized emitter surface; this solves the Tunnel Effect problem. This solution was proved not so efficient after testing as it was on the paper. So currently there is a new model under construction using the latest mini LED technology.

Inspired by Nature

Initially we were inspired by nature and the eyes of a dragonfly.

After some tests and models, we realized that the light output angle should be reduced, and the nature inspired design was creating too much chaos on the design, so we decided to opt for a more industrial design with simplified outlines that would fit also better with the premium and industrial aesthetics we were looking for.